As solar energy continues to dominate the renewable energy sector, new advancements in photovoltaic technologies are shaping the future of solar power. One such cutting-edge development is Heterojunction (HJT) Technology, a revolutionary approach in solar panel manufacturing. This article will explore HJT Technology in detail, discussing its structure, benefits, and prospects. This detailed SEO-optimized guide on Heterojunction Technology is a must-read for anyone interested in increasing efficiency, reducing energy costs, and staying at the forefront of solar technology.

Table of Contents

Introduction to Heterojunction (HJT) Technology

Heterojunction (HJT) Technology is an advanced type of solar cell that combines the best of crystalline silicon and thin-film technologies. By utilizing a combination of amorphous and crystalline silicon layers, HJT cells are designed to maximize efficiency and reduce energy losses. This hybrid approach leads to better performance in various environmental conditions, making HJT a game-changer in the solar energy industry.

Understanding the Structure of HJT Technology Solar Cells

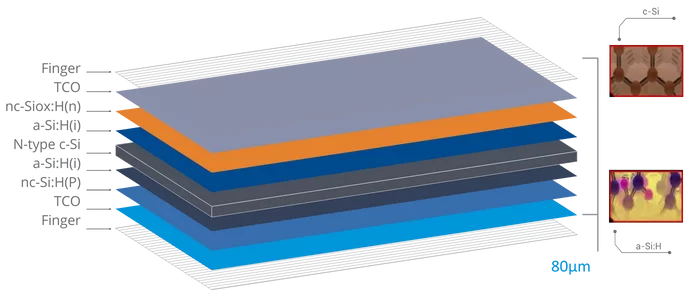

At the heart of Heterojunction (HJT) Technology lies a unique cell structure that distinguishes it from conventional solar cells. An HJT solar cell consists of three primary layers:

1. Crystalline Silicon Wafer (c-Si)

Crystalline silicon (c-Si) modules dominate the PV market with a 95% share, with mono-crystalline (mono-Si) variants making up 70% of c-Si modules in 2019. Over the last decade, technological advancements have increased the efficiency of commercial c-Si modules from 12% to 17%, with some reaching 21% efficiency. Additionally, economies of scale and improved technology have reduced module costs to ₹19.9 to ₹34 per watt. Bifacial modules, which can capture solar radiation from both sides, had a 20% market share in 2020 and are expected to reach 70% by 2030 due to advances in solar cell technology like PERC and PERT.

2. Amorphous Silicon (a-Si) Layers

Amorphous silicon solar cells are the most advanced thin-film solar cells, featuring a p-i-n or n-i-p structure, with a thin i-layer of 0.2-0.5 μm for high absorption. Their absorption frequency (1.1-1.7 eV) differs from silicon wafers (1.1 eV). These cells face challenges like the SWE effect, where performance declines by 15-35% due to light exposure. A multilayer stack design helps balance optical absorption and photoelectric efficiency and may reduce the SWE effect.

Manufactured using plasma-enhanced chemical vapor deposition (PECVD), these cells use materials like stainless steel or plastic. Though their production costs are only slightly lower than crystalline cells, advancements like VHF plasma manufacturing have sped up production and may reduce costs. SnO2 may replace ZnO as a cheaper conductive glass material.

Despite rapid growth (113% in 2003), amorphous silicon cells face limitations, including low photoelectric conversion efficiency, ranging from 4-8% in commercial modules and 13.5% in labs. Their cost-effectiveness and competitiveness remain challenges, though improvements may enhance their market position.

3. Indium Tin Oxide (ITO)

TCO layers are used on the top and bottom of the cell to enhance light transmission and minimize energy losses. Indium tin oxide (ITO) layers are essential in thin-film and heterojunction technology with intrinsic thin layer (HIT) solar cells due to their high conductivity and transparency. In HIT cells, ITO enhances charge carrier collection through low-conductivity amorphous silicon layers.

Current doping methods use toxic gases, necessitating non-toxic alternatives for sustainability. ITO and Al-doped contacts provide a low-temperature processing option, applicable to TOPCon solar cells. While ITO films on a-Si surfaces are well-studied, research on ITO on Al-doped surfaces is limited. To achieve performance comparable to conventional Al back surface fields, contact resistance must be around 1.3 Ω. This paper explores the electrical properties of ITO films on p+ (Al-doped) surfaces in solar cells.

This layered design allows HJT solar cells to overcome some of the limitations seen in traditional crystalline silicon and thin-film technologies.

The Working Principle of HJT Technology Solar Cells

To understand why HJT Technology is so promising, it’s essential to break down the working principle of these solar cells. In a conventional solar cell, the photovoltaic effect occurs in a crystalline silicon wafer that generates an electric current when exposed to sunlight. While effective, this technology has its limits, particularly when it comes to efficiency and long-term degradation.

Heterojunction Technology improves upon this by using both amorphous silicon and crystalline silicon. The crystalline silicon layer acts as the primary light-absorbing material, while thin layers of amorphous silicon are applied on both sides to serve as a passivation layer that reduces electron recombination. This results in higher conversion efficiency and improved temperature performance.

Key Features of HJT:

- Double-Sided Absorption: The bifacial design of HJT cells allows light to be absorbed from the front and rear of the cell, enhancing overall energy capture.

- Improved Passivation: The amorphous silicon layer helps in reducing energy losses due to recombination, significantly boosting cell efficiency.

- Low-Temperature Coefficients: HJT cells perform better at higher temperatures compared to traditional cells, making them ideal for installations in hot climates.

Key Benefits of HJT Solar Cells

Heterojunction (HJT) Technology offers several compelling advantages that make it a superior choice for solar power systems:

1. High Efficiency

HJT (Heterojunction Technology) solar panels are more efficient than conventional PERC (Passivated Emitter and Rear Cell) technology. While PERC uses crystalline silicon for its PN junction, HJT combines two semiconductor materials, including a thin layer of amorphous silicon. HJT cells have an average efficiency of over 22.5%, slightly higher than PERC’s 22%. Additionally, HJT modules offer bifaciality of over 93%, meaning they can generate electricity from both sides.

2. Lower Temperature Coefficient

HJT solar panels have a lower temperature coefficient than conventional crystalline silicon cells, with an efficiency of over 23% at temperatures below 200°C. Their low-temperature coefficient of -0.2%/K enhances efficiency and energy output, even in hot climates. This makes HJT panels ideal for large-scale power generation in warmer environments, where they can produce more energy at a lower cost.

3. Better Bifacial Performance

HJT solar cells have a unique design with symmetrical front and back structures, enhancing their bifacial power generation. These cells achieve over 95% efficiency on the rear side, significantly boosting overall energy output. Their transparent dual-glass design allows light to pass through, improving rear-side generation, and making them ideal for applications like fences and carports. Compared to PERC and TopCon technologies, HJT cells can produce over 30% more energy, making them highly effective for installations where both sides of the panel receive sunlight.

4. High Durability

HJT solar panels are highly durable, lasting up to 30 years compared to the typical 25 years of conventional panels. The amorphous silicon layer reduces degradation and prevents the PID effect, extending the panels’ lifespan and lowering maintenance costs. Maysun Solar offers high-quality, affordable solar modules in Europe, using advanced technologies like PERC, IBC, shingling, double-sided, and half-cut..

5. Improved Low-Light Performance

HJT cells use an i-a-Si thin film between crystalline and doped amorphous silicon layers to passivate surface defects, reducing charge carrier recombination. This results in a higher open-circuit voltage (Voc) of 750mV, enabling better voltage output even in low light. It allows inverters to reach startup voltage faster, extending electricity generation into early morning and evening, maximizing daily energy output.

Comparing HJT with Traditional Solar Technologies

When evaluating Heterojunction (HJT) Technology against traditional solar cell technologies, such as mono-crystalline and poly-crystalline silicon, the differences in efficiency, cost, and performance are stark.

| Parameter | Heterojunction (HJT) Technology | Mono-crystalline Silicon | Poly-crystalline Silicon |

|---|---|---|---|

| Efficiency | 22-24% | 18-21% | 15-18% |

| Temperature Coefficient | Lower | Moderate | High |

| Bifacial Capability | Excellent | Limited | Minimal |

| Cost | Higher upfront | Moderate | Low |

| Longevity | 25-30 years | 20-25 years | 20 years |

From this comparison, it’s clear that HJT solar panels outperform traditional technologies in terms of efficiency and longevity, though they come at a higher initial cost. However, their longer lifespan and improved performance in various conditions make them a worthwhile investment for many applications.

Classification of Heterojunction Solar Cells

Heterojunction Technology solar cells are classified as n-type or p-type based on doping. N-type cells use phosphorus-doped c-Si chips, gaining extra electrons and becoming negatively charged. They are unaffected by boron oxygen, which can reduce cell efficiency. P-type cells, doped with boron, lose an electron and become positively charged. They are preferred for space applications due to their greater resistance to radiation levels encountered in space.

Applications of Heterojunction Technology

- PV Power Station

- Commercial

- Residential

The Global Heterojunction (HJT) Technology Market is also segmented by application, which explores how different industries and sectors utilize the market’s offerings. This segmentation sheds light on the primary drivers of demand, emerging applications, and potential areas for market expansion. By examining usage patterns across industries, the report identifies key application areas that are expected to drive growth, along with challenges and opportunities specific to each sector. For instance, some applications may be fueled by technological advancements or regulatory changes, providing a clear pathway for businesses to align their strategies with market needs.

Current Market of HJT Solar Panels

Interest in HJT solar technology is growing among private Indian companies like Reliance and Goldi Solar, despite the presence of other popular solar technologies. This rising demand has prompted several Indian firms to innovate their solar photovoltaic panels. Last year, Reliance invested $771 million to acquire REC Solar Holdings, a producer of HJT modules and signed a contract with Maxwell Technology for an annual supply of 4.8 GW of HJT cells, including 600 MW of REC Alpha Pure-R cells. The privately owned solar market in India is expected to expand significantly, with durability and efficiency becoming as crucial as cost.

Key Drivers of the HJT Solar Panel Market:

Technological advancements in manufacturing Heterojunction (HJT) Technology solar cells have made production more cost-effective and sustainable, enabling increased scalability without losing efficiency. This growth is expected to drive market expansion, particularly as the solar energy sector strives to improve the efficiency of photovoltaic (PV) cells, which typically convert sunlight to electricity at 15% to 20% efficiency.

However, HJT technology’s higher costs are mainly due to complex manufacturing processes and the use of premium materials, such as silver for metalization. These factors may hinder market growth despite the rising demand for more efficient solar cells.

(HJT) Technology Solar Cell Market Report Acknowledges:

- HIT (HJT) Solar Cell Market size and growth rate during the forecast period.

- Key factors driving the “HIT (HJT) Solar Cell Market”

- Key market trends cracking up the growth of the “HIT (HJT) Solar Cell Market”

- Challenges to HIT (HJT) Solar Cell Market growth.

- Key vendors of the “HIT (HJT) Solar Cell Market”

- Detailed SWOT analysis.

- Opportunities and threats faced by the existing vendors in the “HIT (HJT) Solar Cell Market”

- Trending factors influencing the market in the geographical regions.

- Strategic initiatives focusing on the leading vendors.

- PEST analysis of the market in the five major regions.

Key Market Players in HJT Technology

The global HIT (Heterojunction with Intrinsic Thin-layer) Solar Cell market is segmented by application, end-user, and region, focusing on key manufacturers such as Panasonic, Sanyo, Tongwei, Risen Energy, and others. The report analyzes factors driving market growth, potential segment influences, and future applications. It covers pricing analysis by type, manufacturer, and region, along with industry size, demand, revenue, and market share. The study provides a detailed overview of the industry’s value structure, cost drivers, and overall market environment.

Future Prospects of Heterojunction Technology

The future of Heterojunction Technology (HJT) looks promising. As manufacturing costs decrease and production capacity increases, HJT is expected to become more accessible to mainstream consumers. Research is ongoing to improve the efficiency further and reduce the cost of HJT solar cells, with some projections indicating that HJT could surpass the 25% efficiency mark in the coming years.

In addition, the increasing adoption of bifacial solar panels, which are highly compatible with HJT technology, will likely drive further demand for this innovative solar solution.

Comparative Study Between PERC AND HJT

Technical Comparison Between PERC and HJT

| SR NO | Module Properties | p-PERC | n-PERC | n-HJT |

| 1 | Bifaciality | 70% | 80% | >90% |

| 2 | Micro crack resistance | No | No | Yes |

| 3 | Long-term power degradation rate | High | High | Low |

| 4 | LID/LeTID/PID | Yes | Yes | No |

| 5 | Low light performance | Good | Good | Better |

Commercial Comparison Between PERC and HJT

A study on a 1 MW power plant in Gujarat compared mono PERC and HJT modules, keeping factors like module arrangement and tilt angle constant. Results show that temperature losses in PERC modules are 50% higher, leading to significant energy losses, especially in larger plants. HJT technology, with better surface passivation and low light performance, produces 6% more energy at 1922 kWh/kWp/year and has a 4.7% higher performance ratio (PR) than PERC. These benefits make HJT technology superior in power plant performance.

Conclusion

Heterojunction Technology (HJT) represents a major leap forward in solar panel technology. With its combination of high efficiency, durability, and improved performance in challenging conditions, HJT solar cells are poised to play a significant role in the future of solar energy. Although the upfront cost remains higher than traditional technologies, the long-term benefits and superior performance make HJT an attractive option for those looking to invest in solar energy.

As the world continues to shift towards renewable energy, HJT solar panels could be the key to unlocking the full potential of solar power. Whether you’re a homeowner, a business owner, or a solar industry professional, Heterojunction Technology offers exciting opportunities to harness the sun’s energy more efficiently than ever before.

Get Ahead with HJT Solar Panels

Looking to future-proof your energy strategy? Partner with Soleos Solar Private Limited and harness the latest in solar technology with HJT panels. Contact us now for expert consultation and customized solar installations.